ITEN 3D

3D Printing

Custom 3D Printed Prototypes for Thermoset and Thermoplastics Manufacturers!

Available Bed Size: 3x3x2 ft

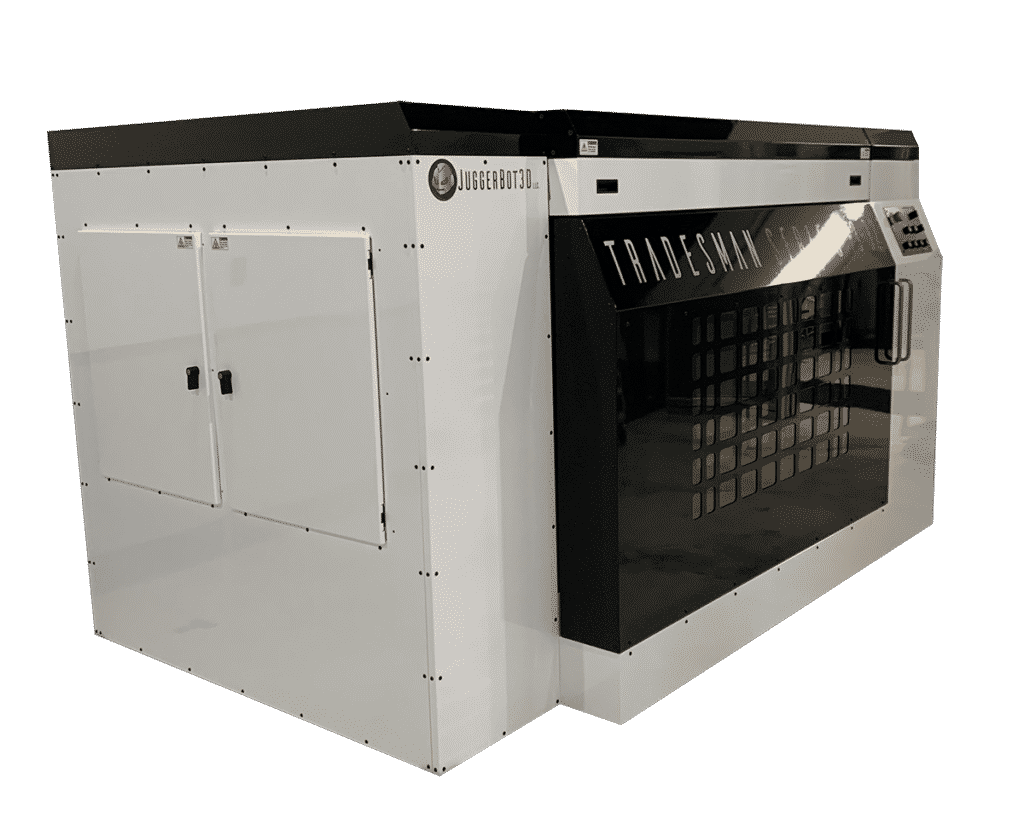

3D Printing with the Tradesman Series™ F3-32 Additive System

Mass Customization

Rapid Manufacturing

Design Freedom

Low Scrap Rate

Additive Manufacturing Process

Fused Filament Fabrication

- Proven additive manufacturing method

- Wide range of performance thermoplastics

- Commodity grades

- High strength

- High temperature

- Very cost-effective

- Can produce complex geometrics

- Excellent mechanical properties

- Preferred technology for larger structures

- Specific opportunities

- Functional prototyping

- Low volume production

- Design and cost improvement

- Customer tooling fixtures and jigs

Direct Ink Writing

- Comparable material to common LSR and HCR materials

- 2-part Polyurethanes, Epoxies, Silicones

- Perfect for flexible parts that require durability

- Chemistry is much more versatile than SLA resins and AM photopolymers

- Great surface finish

Benefits of 3D Prototyping

Save Money

Save Labor

Save Time

Print Quality

Draft

Best for concept models and large parts where surface finish is not a factor.

Standard

Balances build time and precision to showcase better surface finish and tighter tolerances.

Production Quality

Best for parts with tight tolerances and small features, especially if post-processing is not an option.

Materials Used

PLA

ABS

ASA

HIPS

PETG

OBC

PP

PC

Nylon 6/66

Nylon 12

PPE-PS

PVDF

PPS

PEKK

PEEK

Why Choose ITEN?

+

Components / month

Countries and All 50 States

+

Active Parts

+

Parts in History