Manufacturing Overview

With ITEN Industries ISO-9001 certified manufacturing, you receive composite parts that meet exact specifications every time. Our manufacturing operations utilize high-quality molds, well-designed processes, optimal materials, trained employees, and advanced quality control resources to consistently achieve 100% ratings from our customers.

Proudly Made in the U.S.A.

As part of our commitment to furnish high-performance composite products that are value engineered, we take advantage of this full range of manufacturing processes…

3D Printing

Custom 3D Printed Prototypes for Thermoset and Thermoplastics

Manufactures!

Machining Services

ITEN has over 50 years of experience machining parts from our own UL listed high-pressure laminates, vulcanized fibre, glass polyester sheets, pultrusions, and other thermoplastic and thermoset materials.

Fabrication Services

ITEN has over 45 years of experience fabricating parts from our own UL listed high-pressure laminates, vulcanized fibre, glass polyester sheets, pultrustions, and other thermoplastic and thermoset materials.

Pultrusion Processes

The ITEN pultrusion manufacturing process is a cost-effective method of producing UL-listed Politen glass polyester grades in angles, channels, and custom profiles.

Assembly and Finishing Operations

ITEN Industries offers the following value-added services to convert composite components into finished parts and high-level assemblies.

Injection Molding

Our experienced and dedicated professionals operate equipment ranging from 28 tons to 500 tons of clamping pressure, capable of injecting as much as 26 ounces of material per cycle.

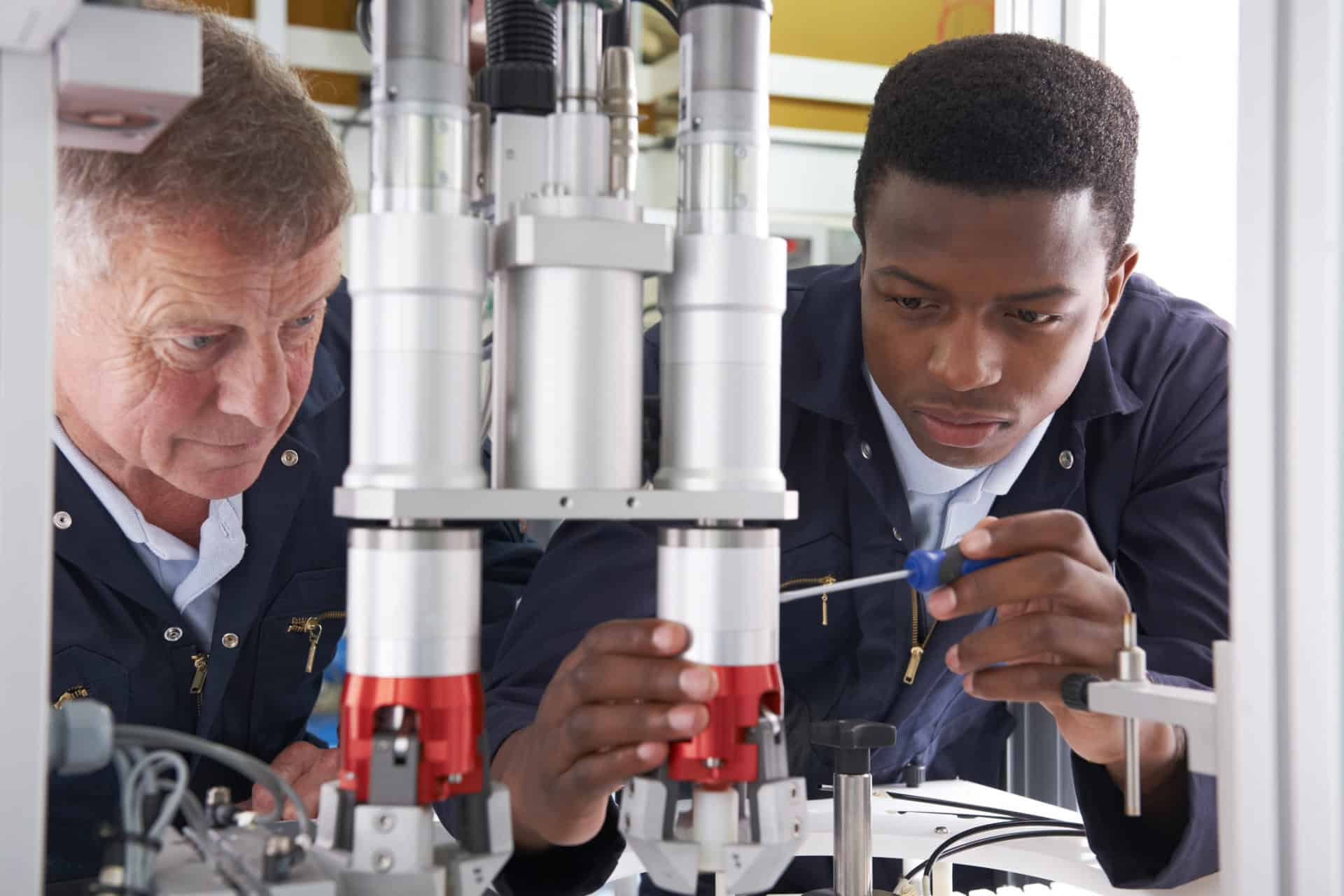

New Product Development

For several decades, customers have been turning to ITEN Industries to take their ideas and turn them into products that are both innovative and cost-effective.

Custom Engineering and Design

ITEN customers are constantly being challenged to introduce more efficient products with reduced costs and increased life cycles.

Tooling and Mold Making

At ITEN Industries, we pride ourselves on creating tooling that delivers consistent parts for many years.

Logistics and Distribution

The flow of components to customer assembly line or delivery of components to customer work site is critical to the timely completion of projects.

Our Services

Why Choose ITEN?